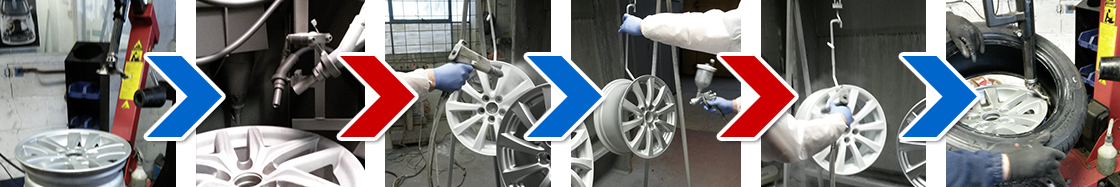

Our Process

The process used here at Primo Alloys has been developed over many years, and takes techniques from OEM wheel manufacturers and those that have been specifically adapted to ensure the best possible finish and adhesion characteristics when applied to older alloy wheels.

If your vehicle, is left with us, it is securely housed within our workshops and its wheels removed.

Tyre / Wheel Inspection

Tyre / Wheel Inspection

Once your tyres are removed they will be inspected and you will be advised of any issues regarding their safety.

The alloys will be checked for buckles and inspected for cracks and other potential problems prior to beginning any refurbishment. You will be contacted and advised accordingly. It is our policy to re-straighten all alloys that are buckled (which may incur a small extra cost) helping to maintain the safety of your vehicle.

Wheel Stripping and Preparation

Wheel Stripping and Preparation

The wheels are then placed into a chemical solution to strip all of the old powder and paint from them. This is followed by a hot chemical cleaning process, ensuring a clean dry wheel for us to work with.

Our state of the art automatic shot blasting machine is used to remove any stubborn residue and key the alloy ready for the coating system.

Badly corroded wheels will require a longer period of blasting to aid the removal of these pitted areas.

Once the wheel has been ground and welded, if necessary, to repair kerb damage. It is ready for the oven and a long de-gassing process to remove trapped air and impurities within the microscopic pores.

Powder Primer

Powder Primer

To ensure a robust and smooth finish ready for application of the topcoat colour, the alloys are primed using powders from the same suppliers to the original wheel manufacturers.

Colour Application

Colour Application

The alloys are then sprayed using the same water-bourne paints as supplied to Europe`s leading wheel manufacturers to help insure colour match and quality.

We stock most of the standard colours used on the alloys of the major car brands. If we do not stock a particular colour we can mix it. Changing the colour of your alloys is limited only by your imagination.

Lacquer Application

Lacquer Application

Now it`s time for the final and most important application, that of the acrylic clear lacquer, over the entire wheel to ensure a strong hard wearing surface.

This finish once baked gives a crystal clear UV stable protection to your alloys.

Tyre fitting / balancing.

Tyre fitting / balancing.

We have invested in the high quality fitting and balancing machines to re-unite your tyres with the newly finished alloys.

We have the capabilities to work with wheels up to 24”dia and work with even the most stubborn run flat technology tyres.

We will always use stick on weights on the inside of the wheels .

The wheels can then be fitted back on to your vehicle and torqued to the correct factory setting.

Should your car be fitted with tyre pressure monitoring system, then we will reset this where possible.